A Guide to Common Processes in Color Carton Printing

In the competitive world of retail and branding, the color carton (彩盒) is a critical touchpoint. It protects the product, captures attention on the shelf, and communicates brand quality. Achieving a standout box involves a combination of printing techniques and post-press finishing processes. Here is a comprehensive overview of the most common technologies used in color carton printing.

I. Core Printing Processes

The choice of printing method depends on design complexity, order quantity, and budget.

- Offset Lithography (Offset Printing)The Standard for Quality: This is the most prevalent technique for high-volume, high-quality color carton production. It involves transferring ink from metal plates (via a rubber "blanket") onto paper or cardboard sheets.Best For: Exquisite, full-color designs with detailed images, gradients, and precise color matching (using the CMYK or Pantone color systems).Advantages: Superior image sharpness, consistent color across long runs, and cost-effectiveness for large quantities. It works excellently on a wide range of paper stocks.

- Digital PrintingThe Agile Solution: This method transfers a digital file directly onto the substrate using toner or inkjet technology, eliminating the need for printing plates.Best For: Short to medium runs, personalized or variable data printing, and rapid prototyping. It's ideal for market testing or limited-edition products.Advantages: No plate costs, faster turnaround for small batches, and exceptional flexibility for customization.

- Flexography (Flexo)The Packaging Workhorse: Often used for corrugated boxes and simpler folding cartons, flexo uses flexible photopolymer plates and fast-drying inks.Best For: Solid colors, simple graphics, and large text. It's highly efficient for long runs on a variety of materials, including non-porous substrates.Advantages: High-speed production, durable prints, and ability to print on a wide array of surfaces.

II. Essential Finishing & Enhancement Processes

These processes are applied after the initial printing to add functionality, texture, and visual appeal.

- LaminationPurpose: To protect the ink from wear, scuffing, and moisture, while also enhancing the visual feel. A thin plastic film (BOPP, PET) is bonded to the printed sheet.Types:Gloss Lamination: Provides a shiny, vibrant finish that makes colors pop.Matte Lamination: Offers a sophisticated, non-reflective, and smooth texture.Soft-Touch Lamination: Creates a velvety, ultra-premium feel that invites interaction.

- CoatingPurpose: Similar to lamination but using a liquid applied and cured (often with UV light).Types:Aqueous Coating: A water-based, environmentally friendly option that provides good scuff resistance and a subtle sheen.UV Coating: A glossy, liquid plastic coating cured instantly with UV light. It can be applied as an all-over coating or as a spot coating to create glossy highlights on specific design elements (contrasting with a matte background).

- Specialty Inks & EffectsMetallic Inks: Add a shimmering gold, silver, or bronze effect.Fluorescent Inks: Create ultra-bright, eye-catching colors.Scratch & Sniff (Micro-encapsulation): Releases a fragrance when scratched.

- Hot Stamping & FoilingPurpose: To add luxurious metallic (gold, silver, holographic) or pigmented foil accents to logos, text, or borders.Process: A heated metal die presses a thin foil film onto the substrate, transferring the design.

- Embossing & DebossingPurpose: To create raised (embossed) or recessed (debossed) textures, adding a sophisticated three-dimensional, tactile element to the carton.Often Combined: with hot stamping for a truly premium effect (e.g., a gold-foiled, embossed logo).

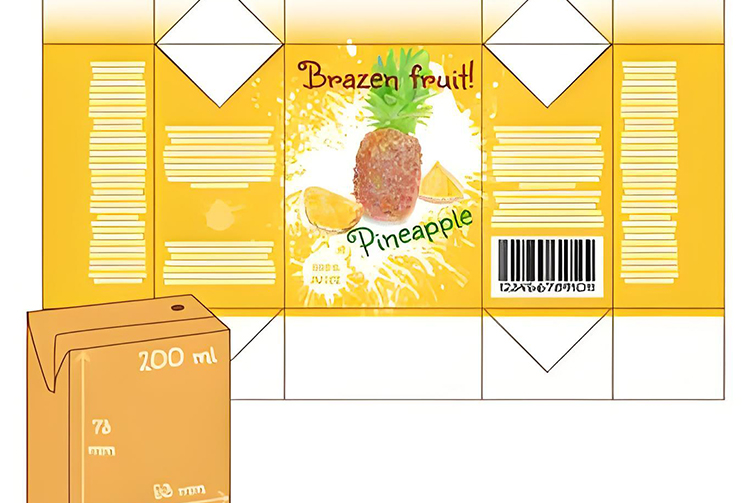

- Die-CuttingThe Shape-Maker: This is a crucial process where a custom-made steel rule die is used to cut the printed sheet into the final, unique shape of the carton. It creates windows, handles, and intricate contours that move beyond a standard rectangular box.

III. Choosing the Right Combination

Selecting the right mix of processes depends on your goals:

- For a Luxury Feel: Consider Offset Printing + Matte/Soft-Touch Lamination + Hot Stamping + Embossing.

- For High-Impact, Shelf-Presence: Offset Printing + Gloss Lamination/UV Spot Coating + Vibrant Specialty Inks.

- For Eco-Friendly Appeal: Offset/Digital Printing + Aqueous Coating on recycled board, using minimal foils.

- For Structural Innovation: A strong die-cut design paired with effective printing.

Conclusion

Modern color carton printing is an art form that blends technology and creativity. By understanding these core printing and finishing processes, brands can work effectively with packaging suppliers to engineer cartons that are not just containers, but powerful brand ambassadors. The most successful cartons strategically combine these techniques to create a memorable unboxing experience that resonates with consumers and drives sales. Always consult with your printer and request physical samples to see and feel the effects before finalizing your order.